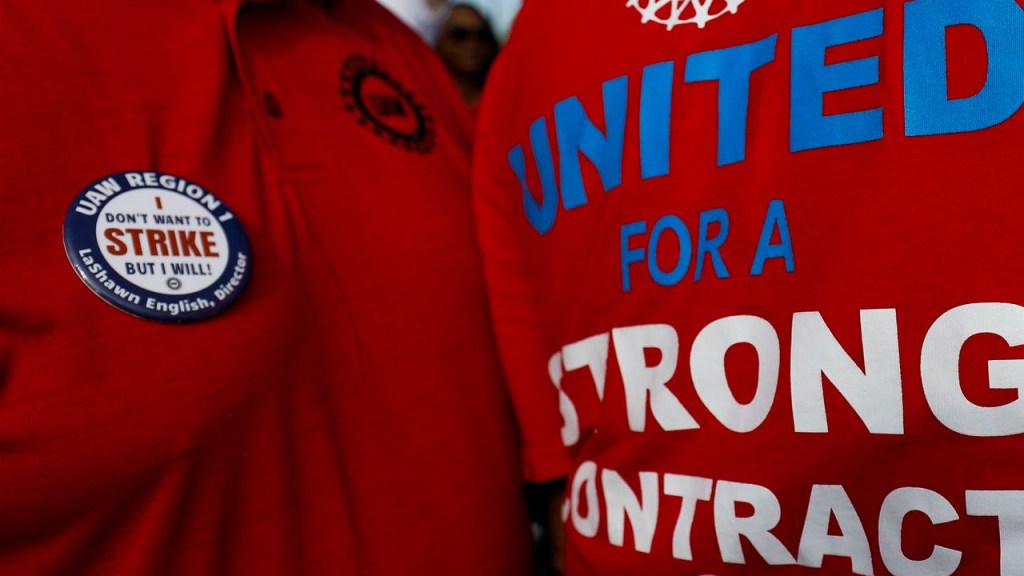

It’s been nearly four years to the day since the last United Auto Workers strike, when 50,000 General Motors employees walked out for a period of six weeks. Now, after a week of anticipation and negotiations, roughly 13,000 UAW members went out on strike as their contracts with Ford, General Motors, and Stellantis expired at midnight on September 14, 2023.

Where Are UAW Workers Striking?

At the time of writing, the strike appears to be of a “tactical” nature, beginning with three assembly plants. At Ford, 3,300 workers are striking at the Michigan Assembly Plant, which produces the Bronco and Ranger. At Stellantis, 5,800 workers are striking at the Toledo Assembly Complex, which builds the Wrangler and Gladiator. At General Motors, the Wentzville Assembly Plant has 3,600 workers on strike. Wentzville makes the Chevrolet Colorado and Express van, and its GMC analogues, the Canyon and Savana.

However, this will likely change. UAW president Shawn Fain said that other plants will be impacted if agreements are not reached in a timely manner. “This strategy will keep the companies guessing,” he said on Facebook Live. “And if we need to go all out, we will. Everything is on the table.”

Sources say that the UAW’s $825 million strike fund could last approximately 90 days. That said, if the tactical approach is continued, only shutting down a few key factories at a time, the strike could last significantly longer.

What Are The Main Goals?

Of course, wages are always front and center. Eyeing huge corporate profits, the UAW was initially seeking a 46 percent raise over the next four years, as well as cost of living adjustments, better benefits, and full pay for new hires (effectively ending the current tier system).

It has since been negotiated down to 35 percent, as the companies claim to stay in business they have to be competitive with non-unionized plants. Currently, labor costs for the Big Three (pay, benefits, premium, pension payments) amount to about $63-$67 an hour. Meanwhile, foreign automakers pay about $55 an hour; Tesla about $45 an hour, for scale. Union demands would increase labor costs for the American automakers to $140-$150 an hour which they say would put them out of play.

In turn, the companies are seeking concessions such as reduced healthcare coverage. The union also wants shorter work weeks, reducing the average full-time schedule to 32 hours per week.

How Have The Automakers Responded?

Versus the last strike, there are new key faces at the bargaining table this time and they are certainly not seeing eye to eye. New UAW President Shawn Fain is a firebrand who has whipped up the troops and raised their expectations. CEO of Stellantis Carlos Tavares is a traditional steely-eyed businessman who is also playing hardball. The environment is also politically charged, with the Biden administration pushing EVs; the union worried that electric vehicle and battery plants require fewer workers and may be paid less. And the backdrop is a societal appreciation of unions.

As of yet, Ford has not responded publicly to the strike, although its vice president of communications issued a statement on social media hours before it began, calling Ford’s last pre-strike offer “historically generous.”

General Motors issued a statement, saying: “We are disappointed by the UAW leadership’s actions, despite the unprecedented economic package GM put on the table. We will continue to bargain in good faith with the union to reach an agreement as quickly as possible for the benefit of our team members, customers, suppliers, and communities across the U.S. In the meantime, our priority is the safety of our workforce.”

Stellantis issued similar remarks: “We are extremely disappointed by the UAW leadership’s refusal to engage in a responsible manner to reach a fair agreement in the best interest of our employees, their families, and our customers. We immediately put the Company in contingency mode and will take all the appropriate structural decisions to protect our North American operations and the Company.”

What Will The Effect Be?

The strike comes at a time when serious momentum around production is just beginning. Though some supply chain issues are still present, so far this year, inventory statistics and overall price levels have seemingly been returning to normal.

“With increased inventory we are seeing the increase in incentives: 5.2 percent of MSRP in August,” said Alex Yurchenko, senior vice president and chief data science officer at industry analyst Black Book. “It is still way below pre-pandemic levels (about 10.5 percent of MSRP) but much higher than last year (about 2.5 percent of MSRP).”

Automakers tend to try to stock up on inventory when the end of a union contract is approaching, but in recent times this has obviously been far more difficult. Stellantis and Ford declined to provide any context around dealer inventories and whether they’ve been actively building up to fend off the risk of a strike. However, GM’s director of finance and sales communications, David Caldwell, called GM’s U.S. inventory “consistent,” only up about 4 percent compared to the first quarter.

A significant work stoppage will only make lots emptier and wait times longer. Shutting down factories from all three companies for six weeks could result in a production loss of around 800,000 vehicles.

Shortages will again begin to impact the rest of the market. If the strike lasts longer than 30 days, used car prices will likely begin to spike once more. New car prices will likely be affected by the loss of incentives as cost-recouping measures. Labor cost only accounts for about 10 percent of total new-car production expenses, so increases in this area will be less major in the long run.

Even though UAW workers make less than half the cars made in the United States, it is a global industry and automakers share suppliers. If suppliers are negatively impacted by the strike, it reduces their ability to get parts to other automakers, so everyone ends up feeling the impact.

Depending on the results of the strike, future boardroom decisions might move production to lower-cost countries or regions, which means job losses. All North American manufacturing already faces the challenge of keeping up with China. At the very least, it will push key car-making states like Michigan into a recession.